Automotive

Automotive

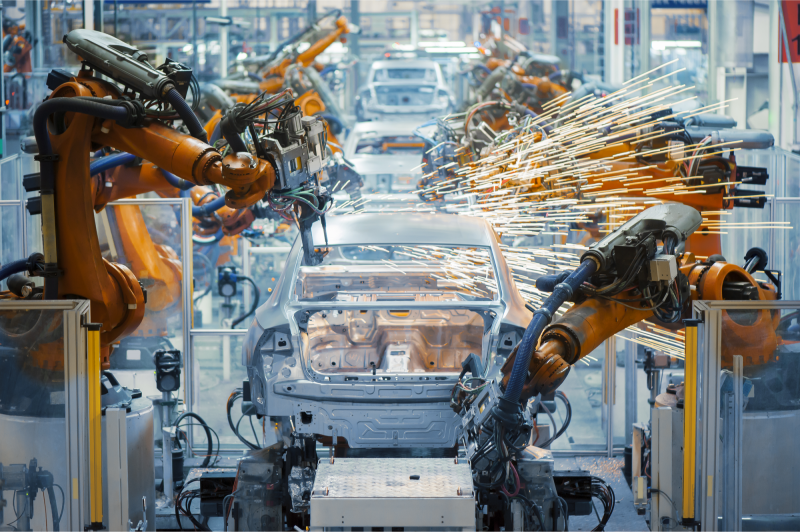

Over the past decade, the number of electronic components going into consumer vehicles and being used across the automotive industry has increased tenfold. From the intricate cable assemblies in windscreen wipers and LED lighting in cars to the wheel balancing units used for tyre changing and sensor devices that weigh vehicles.

As a result, we have adapted our automotive electronic manufacturing services — manufacturing anything from bespoke cable assemblies and custom-made wiring harnesses to PCB prototypes and electronic module sub-assemblies — to reflect demand in the industry. We work in partnership with providers supplying tier-one automotive contractors to assist with component selection, finding the best solution to ensure their products meet the high standards and performance requirements expected of manufacturers in this field.

Demanding the highest quality

Much like the industrial sector or oil, gas and water industry, automotive has stringent requirements and demands the highest quality levels. A car is one of the harshest environments you can put components or electronic modules into — as such, meticulous attention to detail is essential, and given the final applications, the reliability and safety of all components involved are critical.

At Swan EMS, we combine the need for reliability, short lead-times, competitive costs and specialist requirements to provide first-class electronics manufacturing services to automotive companies.

We have a vast array of experience and knowledge working on projects within the automotive sector and meeting all the requirements of the industry. We only manufacture electronics to the highest quality levels and IPC-A-610 and IPC/WHMA-A-620 standards of workmanship, and we also support customers in the PPAP (production part approval process) and register all parts on the IMDS (international material data system).

Not only do we manufacture cutting-edge and high-quality technology, but we can also protect your electronics through our in-house process of conformal coating, which prevents damage from moisture, dust or contaminates in harsh and hazardous environments.